RKE2200B1-V-G2

|

Cooling capacity |

: |

8.7kW |

|

Operating Ambient Temp. Range |

: |

-5~43℃ |

|

Operating Liquid Temp. Range |

: |

5~35℃ |

|

Control Accuracy |

: |

±0.1 ℃ |

Features

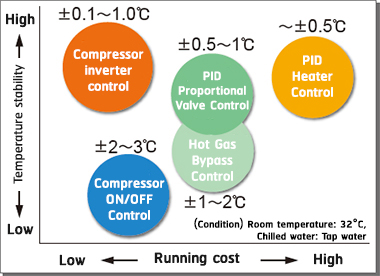

No Trade-Off between Low Energy and High Accuracy Control -- Now Orion Offers Both!

|

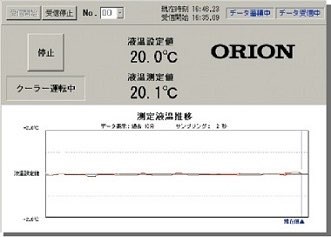

Our inverter controlled compressor responds to fluctuating workloads linearly, achieving highly accurate (User can choose between "High-accuracy" and "Energy saving" modes in response to low-load conditions.)

|

|

|

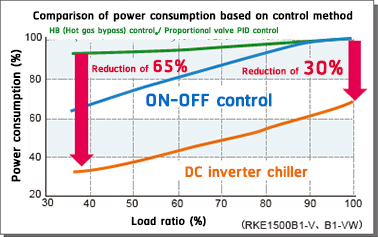

As much as 65% Energy Savings Possible |

Temperature Control Accuracy to ±0.1 °C* |

|

|

Even compared with power saving ON/OFF type chillers, our DC Inverter control models offer energy savings of 30 % at full load. And when compared with temperature-stable hot gas bypass or PID proportional valve controlled chillers, a 65 % reduction in energy requirements is possible.

|

Precise control even for applications that have severe temperature management requirements. Its extreme versatility makes it suitable for a wide range of applications, including precision-production-use lasers, analysis devices, semiconductor manufacturing, and many others. ※ Under stable load and ambient temperature.

|

Specifications

| Model | RKE2200B1-V-G2 | |||

| Performance | Compressor output (50Hz) | HP | 2.3 | |

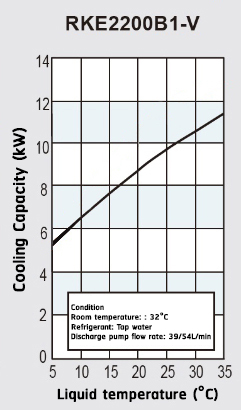

| Cooling capacity (50Hz)*1 | KW | 8.7 | ||

| TR | 2.5 | |||

| BTU/h | 29,600 | |||

| Ambient Temp. Range | ℃ | -5~43 | ||

| Working temperature range (Liquid temperature) | ℃ | 5~35 | ||

| Control accuracy*4 | ℃ | ±0.1 (Stable load/ambient temperature/power supply) | ||

| ±0.5 (Load fluctuating within ± 10% of the current load) | ||||

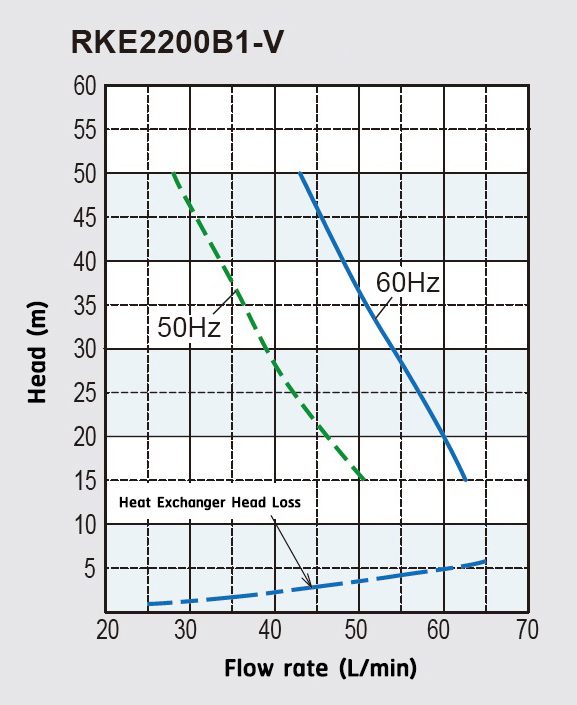

| Min. operating circulation rate (50/60Hz) | L/min | 28/43 (Head 50m) | ||

| Power specification | Power source*2 | V(Hz) | Three-phase 200±10%(50/60), 220±10%(60) | |

| Power consumption*1 | kW | 4.6/4.7, 4.7 | ||

| Electric current*1 | A | 16/17, 17 | ||

| Power capacity*3 | kVA | 6.5 | ||

| Breaker capacity | A |

30*6 Current sensitivity 30mA high-speed type |

||

| Operation control method |

Compressor revolution control |

|||

| Equipment detail | Refrigerating compressor | Structure | Fully sealed rotary type (Inverter-driven) | |

| Output | kW | 1.7 | ||

| Condenser | Fin and tube forced air cooling | |||

| Heat exchanger | Structure | Plate type heat exchanger | ||

| Material | SUS316 (Brazing: Cu) | |||

| Discharge pump | Structure | Cascade type | ||

| Output | kW | 0.75 | ||

| Water tank capacity | L | Approx. 20 | ||

| Refrigerant | R-410A | |||

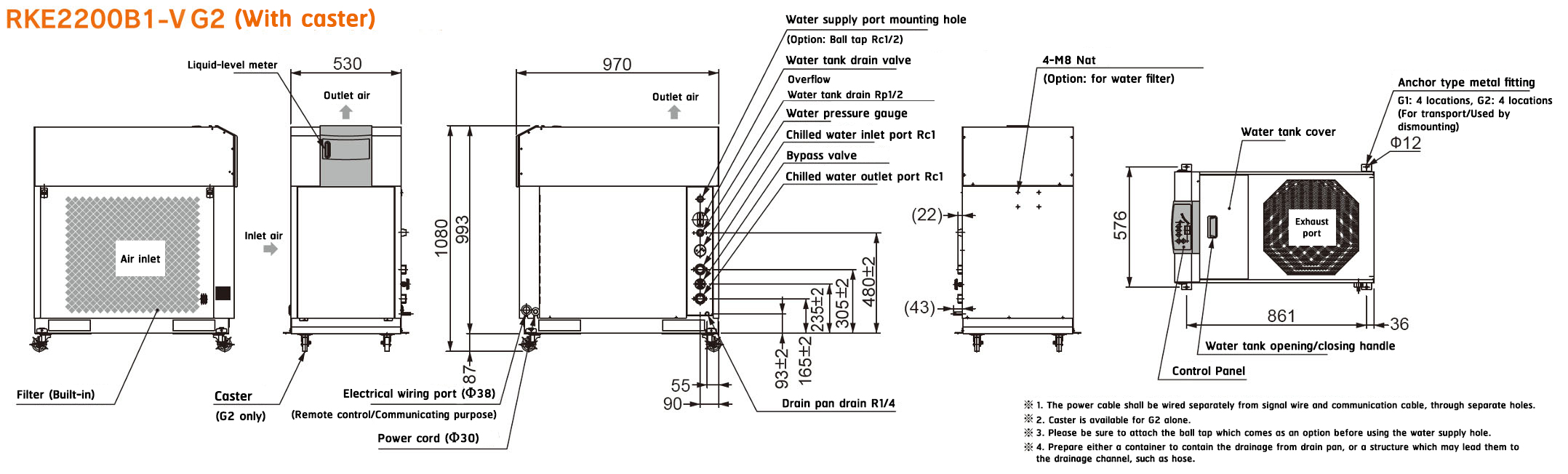

| External dimensions (Height x Length x Width) | mm | 1080×970×530 | ||

| Product mass (Dry weight) | kg | 140 | ||

| Operating noise level (50/60Hz)*5 | dB | 62/64 | ||

| *1 For operation on air-cooled machines when the chilled water temperature is 20 °C and the ambient temperature is 32 °C. Cooling capacity is at least 95% of listed figures. | ||||

| *2 Power supply voltage phase imbalance shall be maintained to within ±3%. | ||||

| *3 Max. electric current upon operating under the shown specification. | ||||

| *4 Exclude cases such as, at start-up, whenever the cooling load is low, or whenever turning the compressor ON-OFF | ||||

| *5 Operation noise shown is of frontward 1m , and a height of 1m. | ||||

| *6 Overload protection combination circuit breaker is built-in as a standard feature. | ||||

| Note 1) Recommended fluid (Cooling water) for the device is pure water, or industrial ethylene glycol solution with 30 - 40% concentration. Please use Aurora brine, or Nybrine Z-1 as the industrial ethylene glycol. Electrical conductivity shall be 1µS/cm or lower for the pure water. If you may wish to use the 30 - 40% lowly concentrated ethylene glycol solution, please be informed that the cooling capacity drops by approximately 10%. | ||||

| Note 2) Equipment exhaust heat rate (kW) is approximately 1.3 times of the cooling capacity. | ||||

External Dimensions

Cooling Capacity

Pump characteristics curve