RKS753J-V-00000/ RKS1503J-V-00000

|

Cooling capacity |

: |

1.1 kW (RKS753J-V-00000) 2.4 kW (RKS1503J-V-00000) |

|

Operating Ambient Temp. Range |

: |

10~40℃ |

|

Operating Liquid Temp. Range |

: |

15~35℃ |

|

Control Precision |

: |

±2.0℃ |

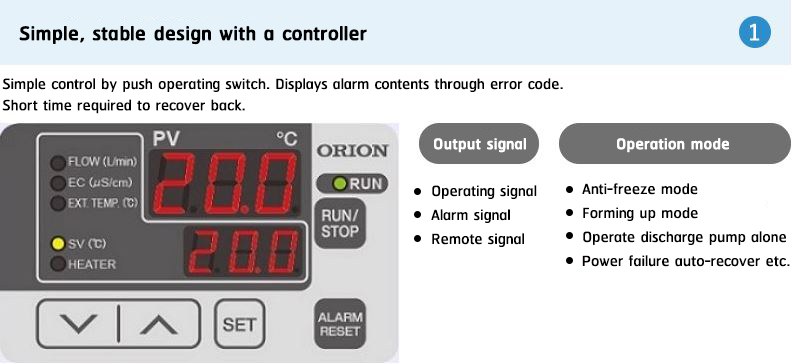

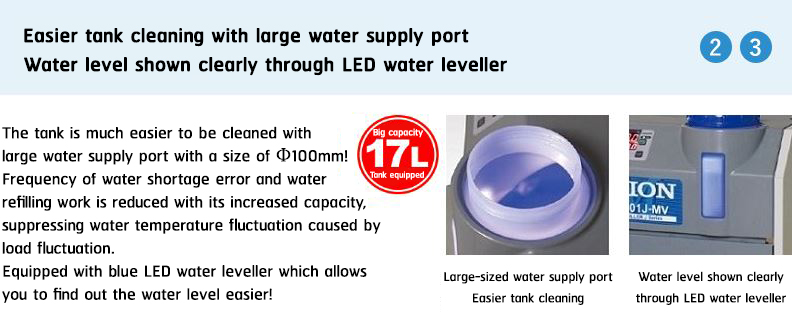

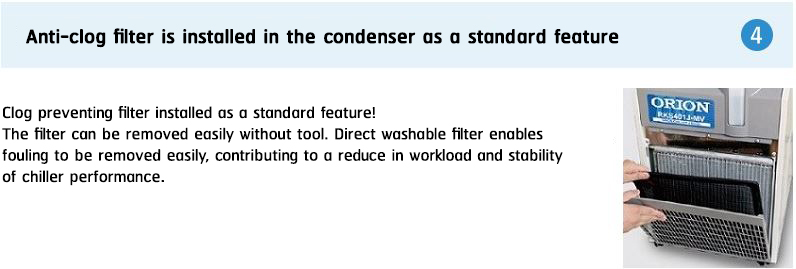

Features

Made even easier to use!

Common for all RKS J series models

|

|

||||

|

|

|||||

|

|

|||||

|

|||||

Accessories

Many functional specifications available to match your application

The list of accessories is available on a different page. Please click the link below to take a look.

Specifications

| Model | RKS753J-V-00000 | RKS1503J-V-00000 | |||

| Performance | Compressor output (50Hz) | HP | 1.1 | 2.4 | |

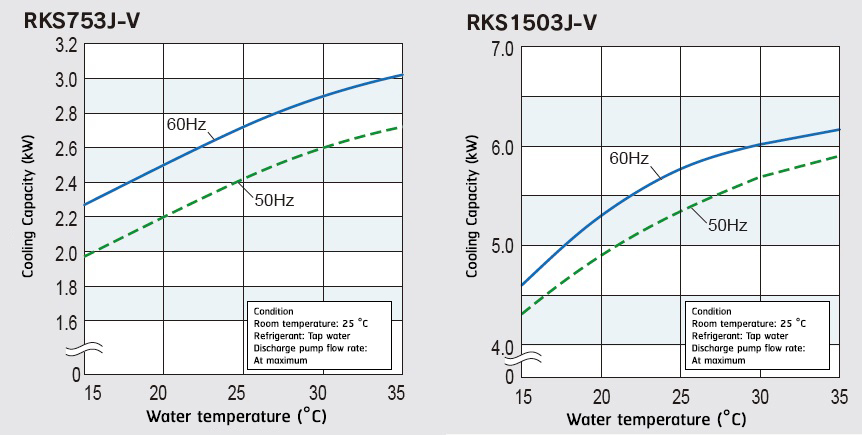

| Cooling capacity (50Hz)*1 | KW | 1.8 | 4.1 | ||

| TR | 0.5 | 1.2 | |||

| BTU/h | 6,100 | 13,900 | |||

| Ambient Temp. Range | ℃ | 10~40 | |||

| Operating temperature range (Liquid temperature) | ℃ | 15~35 | |||

| Operating Water Pressure | Mpa | 0.05~0.2/0.3(50/60Hz) | 0.1~0.5 | ||

| Control accuracy*4 | ℃ | ±2.0 | |||

| Min. Operating circulation rate (50/60Hz) | L/min | 10 (Head 20/30m) | 12/21 (Head 50m) | ||

| Power specification | Power source*2 | V(Hz) | Three-phase 200±10%(50/60)・220±10%(60) | ||

| Power consumption (50/60Hz)*1 | kW | 0.9/1.1, 1.1 | 1.8/2.2, 2.2 | ||

| Electric current (50/60Hz)*1 | A | 4.1/4.1, 4.1 | 6.8/7.4, 7.4 | ||

| Power capacity*3 | kVA | 2.0 | 4.2 | ||

| Breaker capacity*5 | A | 10 | 15 | ||

| Operation control method | Compressor ON/OFF Control | ||||

| Equipment detail | Refrigerating compressor | Structure | Fully sealed rotary type | ||

| Output | kW | 0.85 | 1.8 | ||

| Condenser | Corrugated fin & Parallel flow tube type | ||||

| Heat exchanger | Structure | Plate type heat exchanger | |||

| Material | SUS316 (Brazing: Cu) | ||||

| Discharge pump | Structure | Cascade type | |||

| Output | kW | 0.25 | 0.4 | ||

| Water tank capacity | L/min | Approx. 17 | |||

| Refrigerant | R-410A | ||||

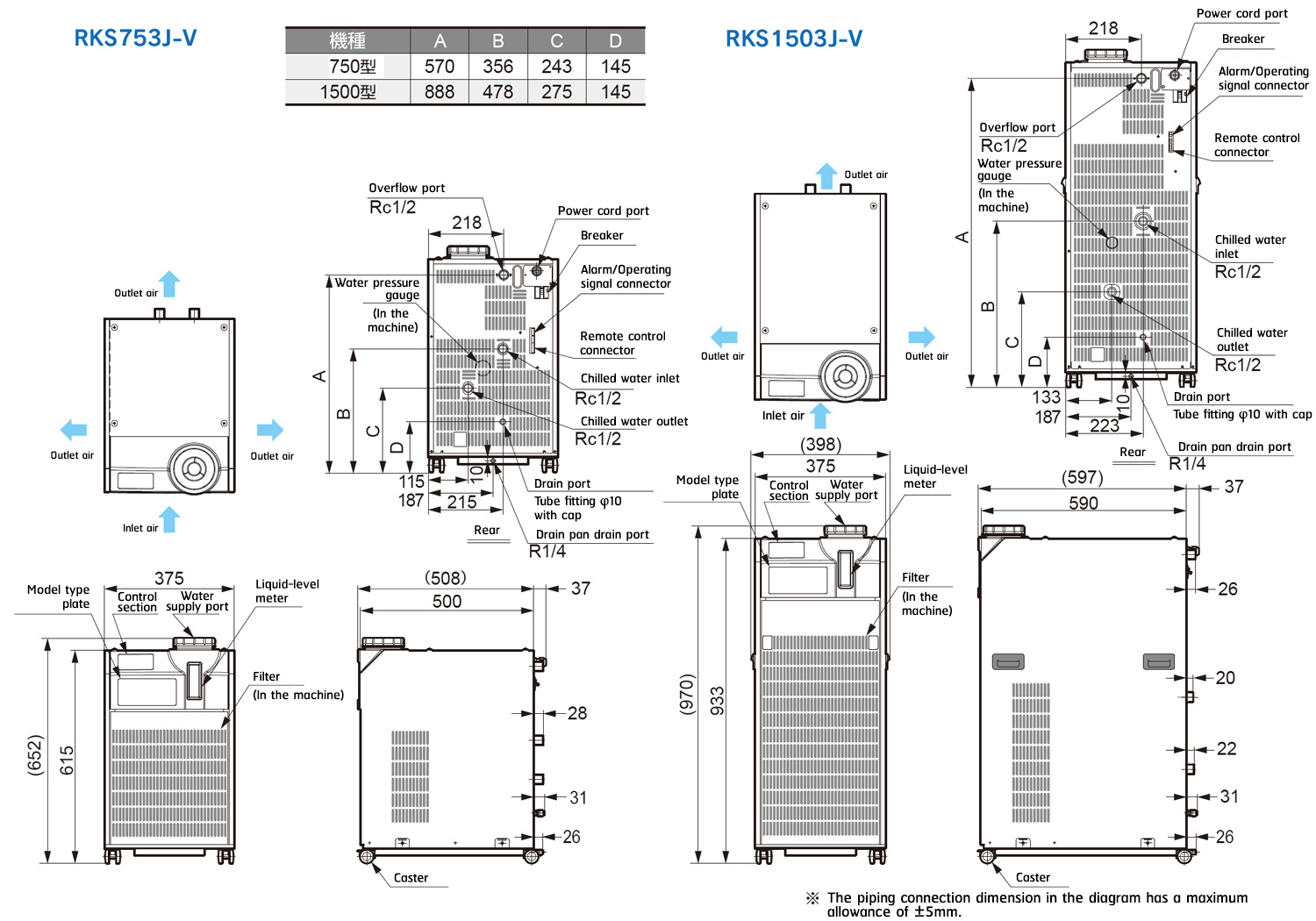

| External dimensions (Height x Length x Width) | mm | 615×500×375 | 933×590×375 | ||

| Product mass (Dry weight) | kg | 45 | 67 | ||

| Operation noise level (50/60Hz)*6 | dB | 61/63 | 63/66 | ||

| *1 Under the following conditions: Chilled water temp.: 20 °C, Ambient temp.: 32 °C, Max. discharge pump circulating load. Cooling capacity is at least 95 % of listed figures. Heating capacity will change according to operating conditions. | |||||

| *2 Source voltage phase unbalance should be less than ±3 %. | |||||

| *3 The figure noted is when the equipment is operating at the highest capacity of its normal operating range. | |||||

| *4 When the current load is continuously within ±10 %, and the ambient temperature is stable. However does not include starting times or when the heat-load exceeds the chiller capacity. |

|||||

| *5 Comes standard with a built-in overload protection circuit breaker (NFB). | |||||

| *6 Operating noise levels are from a position of 1 m in front of the product and at a height of 1 m. | |||||

| Note 1) Liquid (chilled water) that can be used are either clean water and a 30 to 40 % ethylene glycol solution. Note that there will be a drop in cooling capacity of 10 % if using a 30 to 40 % ethylene glycol solution. Alternatively, if deionized water is to be used, it should have an electrical conductivity of at least 1 μs/cm. |

|||||

| Note 2) Heat output from the unit (in kW) is approx. 1.3 times that of the cooling capacity. | |||||

| Note 3) Depending on the operating environment, condensation may form on piping inside the product, and temporary leakage of water from the pump mechanical seals may also occur, therefore a drain pan should be installed if required. | |||||

External Dimensions

Cooling Capacity

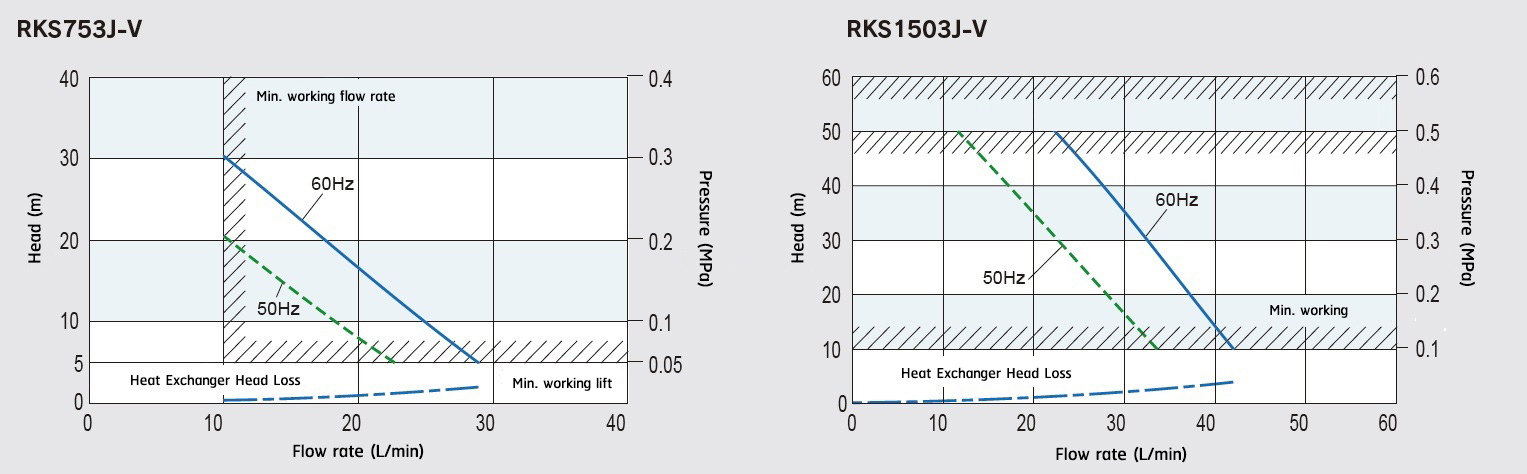

Pump characteristic curves