RKS-JM Small tank cooler (air conditioner)

High precision temperature control system + high pressure inverter pump + support working in hot weather conditions

RKS402J-MV-00000/ RKS752J-MV-00000/ RKS1502J-MV-00000

Cooling capacity (50/60Hz)

0.8~1.6kW

Controllable temperature range

5~45℃

Temperature range of liquid used

5~40℃

Temperature control accuracy

±0.1 ℃

Special features

Convenient and modern, easy to use, safe and compatible with all RKS J(M) series machines.

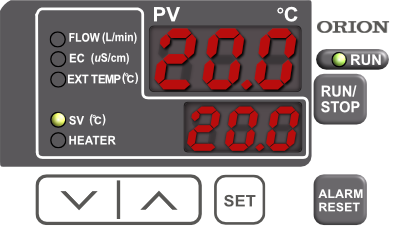

1. The system control screen is easy to understand and convenient to control.

2. Large water pipe in the tank, convenient for cleaning.

3. The display shows the water level in the tank.

4. There is a standard filter to prevent clogging in the pipe.

The machine design is easy to understand and convenient to control.

Control operation with a single on/off button, send an alarm when an abnormal event is detected, and quickly reset the system.

- Power light

- Warning light

- Remote control signal

- Anti-ice mode

- Forming Up Mode

- Separate water pump installation

- Self-reset system after power failure, etc.

Large water pipe in the tank, convenient for cleaning. There is an LED display showing the water level clearly.

The water tank has a maximum diameter of 100 mm.

Easy to clean!

But it also reduces the rate of leakage or errors in water level control very well. There is an LED screen to clearly show the water level.

Easy to clean

It shows the water level clearly.

There is a standard filter to prevent clogging in the pipe.

There is a standard filter to prevent clogging in the pipe!

The filter can be removed for easy cleaning.

Cleaning the filter will reduce the damage rate of the cooling unit.

Accessories

มีMany additional applications to support usage

The details of the accessories are listed on other pages. Please study before use.

>Accessories can be used with all models of RKS J (M).

Specifications

| Model | RKS402J-MV-00000 | RKS752J-MV-00000 | RKS1502J-MV-00000 | |||

| ability | Produced pressure (50Hz) | HP | 0.8 | 1 | 1.6 | |

| Cooling capacity produced (50Hz)*1 | KW | 1.1 | 1.8 | 3.7 | ||

| TR | 0.3 | 0.5 | 1.1 | |||

| BTU/h | 3,700 | 6,100 | 12,600 | |||

| Heat generated (50Hz)*1 | kW | 0.53/0.53 | 0.6/0.6 | 1.1/1.1 | ||

| Controllable temperature range | ℃ | 5~45 | ||||

| Temperature range of liquid used (liquid temperature) | ℃ | 5~40 | ||||

| Cold water pressure | Mpa | 0.05~0.3 | 0.1~0.6 | |||

| Accuracy level*4 | ℃ | ±0.1 | ||||

| Minimum volume used for circulation within the tank (50/60Hz) | Liters/minute | 10 (effect 30m) | 18 (effect 60m) | |||

| Characteristics of electric current usage | battery*2 | V(Hz) | One phase 200~230±10%(50/60) | One phase 200~230(50/60)-5%,+10% | ||

| Electrical energy used (50/60Hz)*1 | kW | 0.9/1.0 | 1.1/1.2 | 2.0/2.5 | ||

| Electric current (50/60Hz)*1 | A | 3.8/4.7 | 5.2/5.4 | 9.5/11.3 | ||

| Battery size*3 | kVA | 1.5 | 2.0 | 4.2 | ||

| Size of circuit breaker*5 | A | 10 | 15 | 30 | ||

| Motor characteristics | Power supply control system | |||||

| Installation details | Pressure regulator for cooling pipe | structure | Rotary control system | |||

| Energy produced | kW | 0.6 | 0.75 | 1.2 | ||

| condenser | Colgate Fin and Tube Parallel System | |||||

| Cooling machine | structure | Heat transfer plate | ||||

| System condition | SUS316(brazing:Cu) | |||||

| Water pump | โครงสร้าง | Cascade system | ||||

| Energy produced | kW | 0.25 (Centrifugal Inverter) | 0.4 (Centrifugal Inverter) | |||

| Actual water tank volume | Liters/minute | about 17 | ||||

| Coolant | R-410A | |||||

| External dimensions (height*depth*width) | Mm. | 615×500×375 | 933×590×375 | |||

| Machine volume (dried volume) | กก. | 42 | 45 | 72 | ||

| Noise during operation (50/60Hz)*6 | dB | 59/60 | 61/62 | 64/65 | ||

*1 The achievable pressure level at a cold water temperature of 20℃, an outdoor temperature of 32℃, and a capacity of 95% may be affected by heat generated during operation.

*2 Try to control the current so that it does not fluctuate beyond the specified value of ±3%.

*3 Maximum current at full load.

*4 Use the machine continuously and the load does not exceed ±10% and the current is constant, except when the machine is heavily loaded when starting operation.

*5 Install a standard circuit breaker (NFB) in the machine.

*6 Measure the noise level at a distance of 1 meter in front of the machine and 1 meter above the machine.

Warning 1) This chiller uses ethyl alcohol with a concentration of 30-40%, which contains pure brine (Aurora Brine) for Z-1

Or must use pure water 1µS/cm as a conductive medium. If using ethyl alcohol with a concentration lower than 30-40%, the cooling efficiency will decrease by about 10%.

Warning 2) The power generated by the heat (kW) is about 1.3 times of the power generated.

Warning 3) The working environment may cause the liquid in the pipe to freeze. Please install special equipment such as welding pipe, drain pipe.

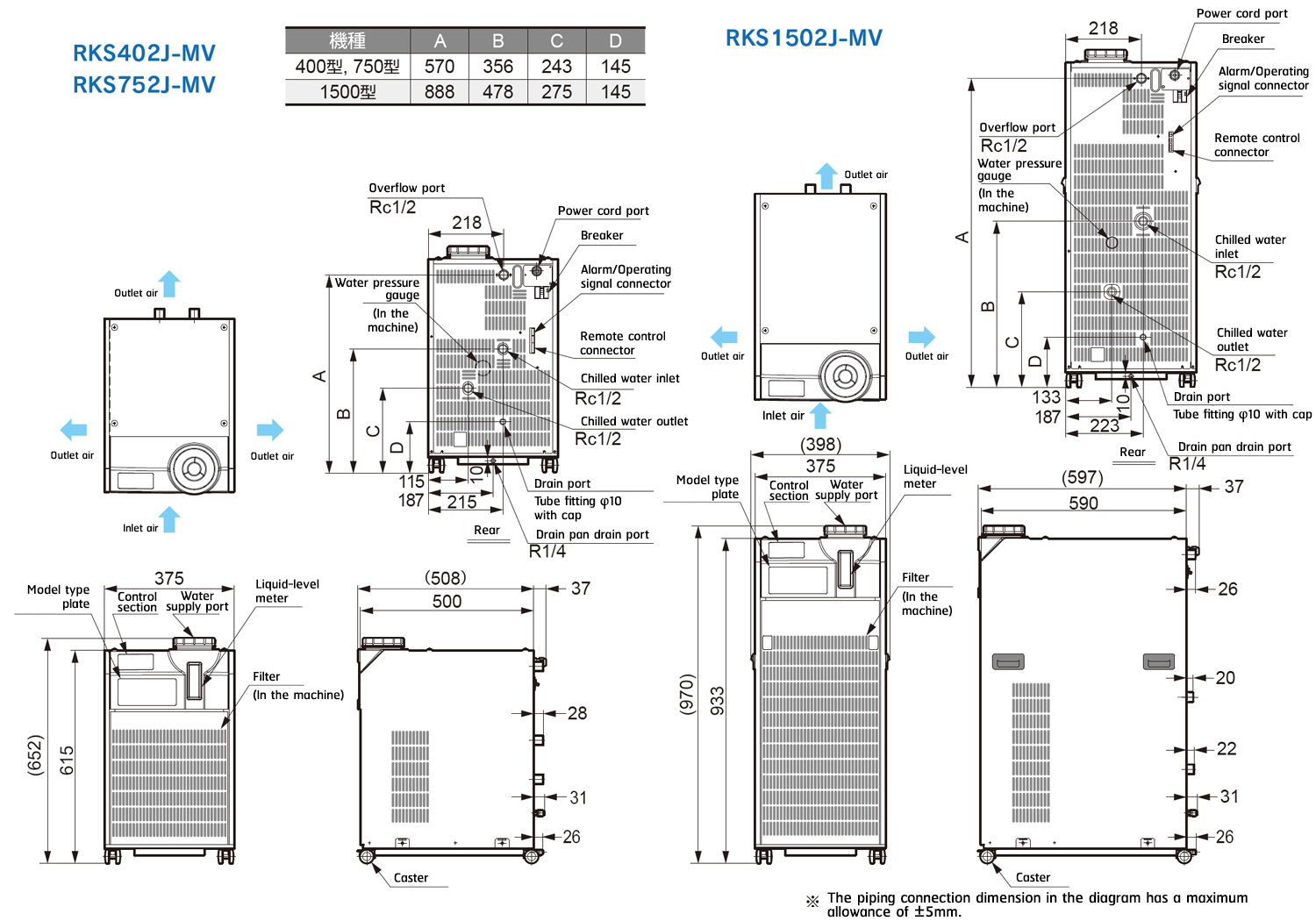

External type

*The distance shown in the diagram may deviate from the actual value by approximately ± 5 mm.

Coolant pipe diagram

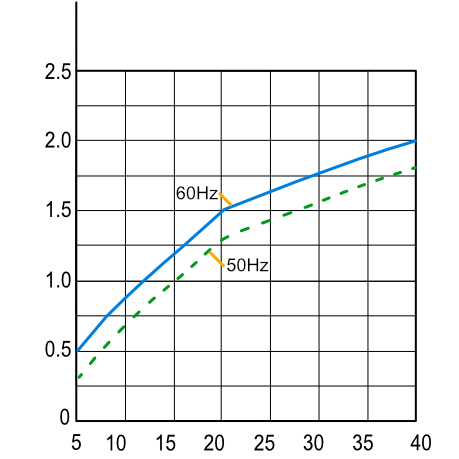

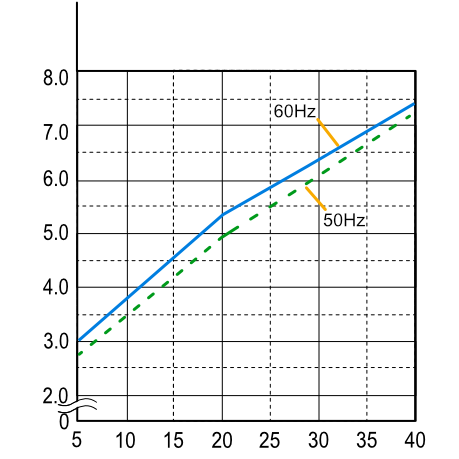

402J-MV

Cooling capacity (kilowatt)

Condition

Room temperature: 25°C

Coolant: Water pipe

Pump power: Maximum

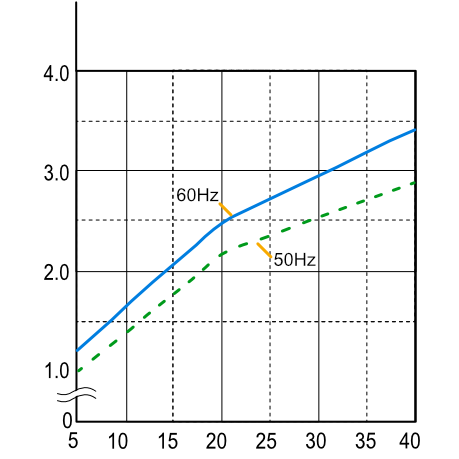

RKS752-MV

Cooling capacity (kilowatt)

Condition

Room temperature: 25°C

Coolant: Water pipe

Pump power: Maximum

1502J-MV

Cooling capacity (kilowatt)

Condition

Room temperature: 25°C

Coolant: Water pipe

Pump power: Maximum

Water pump inlet pipe diagram

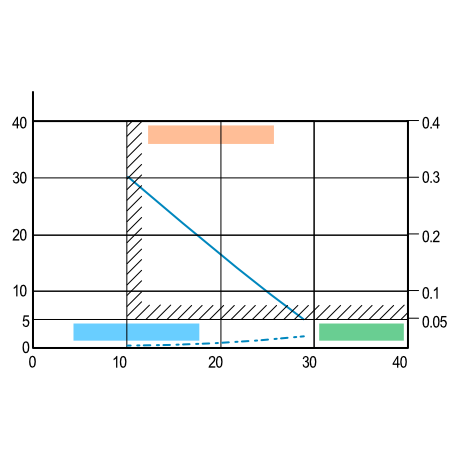

RKS 402/752/-MV

Pump pressure level (m)

Water volume (liters/minute)

Minimum usage amount

The level of cold water that may be lost

Vibration resistance level

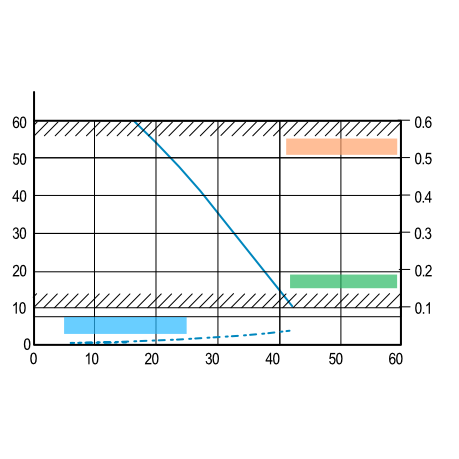

RKS1502-MV

Pump pressure level (m)

Water volume (liters/minute)

Maximum usage level

The level of cold water that may be lost

Minimum usage level

Download documents