RKE DC Inverter Chiller (Air Cooled)

Excellent specifications, energy saving, precise temperature control (±0.1℃)

RKE2200B1-V-G2

Cooling capacity

8.7kW

Temperature range in which the machine can operate

-5~43℃

Settable water temperature range

5~35℃

Temperature control accuracy

±0.1 ℃

Special Features

By combining two technologies, energy saving and high temperature control accuracy, ORION offers both.

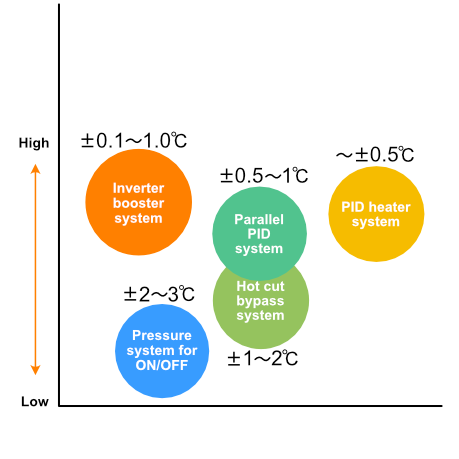

Temperature stability

Small < Operating Cost > Large

The compressor is controlled by an inverter, saving energy and controlling the temperature accurately. With Orion’s special technology, the control is stable and precise continuously. (The user can choose between “High Precision Mode” and “Energy Saving Mode” in case of low working load.)

Save energy up to 65%

Compared with chillers controlled by on/off compressor system,

our DC inverter chillers

can save 30% energy in 100% operation.

And compared with chillers controlled by thermal bypass or PID system,

our DC inverter chillers can save 65% energy.

Accuracy level ±0.1℃* from actual use results

With strict temperature control, it can support various high-precision work, such as high-precision laser work, conductive parts manufacturing machinery, multi-step continuous processing machinery, etc.

Specification

| Model | RKE2200B1-V-G2 | |||

| Ability | The pressure generated (50Hz) | HP | 2.3 | |

| Cooling capacity produced (50Hz)*1 | KW | 8.7 | ||

| TR | 2.5 | |||

| BTU/h | 29,600 | |||

| Controllable temperature range | ℃ | -5~43 | ||

| Temperature range of liquid used (liquid temperature) | ℃ | 5~35 | ||

| Accuracy level*4 | ℃ | ±0.1 (Machine load・Outside temperature・Power consumption) | ||

| ±0.5 (The machine is in continuous use and the machine load does not exceed ±10%) | ||||

| Minimum volume used for circulation within the tank (50/60Hz) | Liters/minute | 28/43 (Pressure 50m) | ||

| Characteristics of electric current usage | Energy source*2 | V(Hz) | Three phase 200±10%(50/60), 220±10%(60) | |

| Electrical energy used*1 | kW | 4.6/4.7, 4.7 | ||

| Electric current*1 | A | 16/17, 17 | ||

| Battery size*3 | kVA | 6.5 | ||

| Size of breaker | A | 30*6 High voltage current 30mA |

||

| Motor characteristics | Pressure control system | |||

| Installation details | Coolant pressure regulator | structure | Closed circuit rotor (inverter) | |

| Energy produced | kW | 1.7 | ||

| Condenser | Fin and tube cooler | |||

| Cooling machine | โครงสร้าง | Heat transfer plate | ||

| System condition | SUS316(brazing:Cu) | |||

| Water pump | structure | Cascade system | ||

| Energy produced | kW | 0.75 | ||

| Water tank capacity | L | About 20 | ||

| cool | R-410A | |||

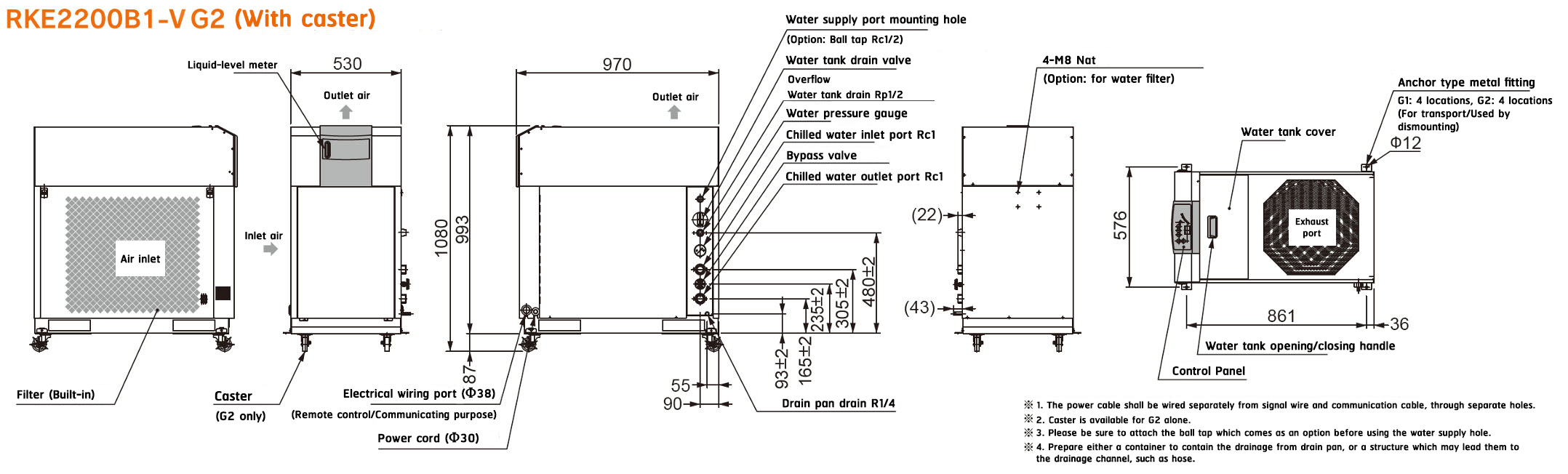

| External dimensions (height*depth*width) | Mm. | 1080×970×530 | ||

| Machine volume (dry volume) | kg. | 140 | ||

| Working noise (50/60Hz)*5 | dB | 62/64 | ||

*1 Chilled water level 20℃ and outside temperature 32℃ Chilled water temperature is achieved when operating at 95% of capacity.

*2 Try to control the electric current so that it does not fluctuate beyond the specified value of ±3%.

*3 Maximum current from full-rate operation.

*4 Except when turned on/off by pressure system, it may cause a load on the unit.

*5 Measure the sound level at a distance of 1m in front of the unit and 1m above the unit.

*6 Install a circuit breaker to prevent electric leakage.

Warning 1) This chiller uses ethyl alcohol with a concentration of 30-40%, including pure brine (Aurora Brine) for Z-1.

Or, pure water of 1µS/cm must be used as a conductor. If ethyl alcohol with a concentration lower than 30-40% is used, the cooling efficiency will decrease by approximately 10%. Warning 2) The heat generated (kW) is approximately 1.3 times the cooling power produced.

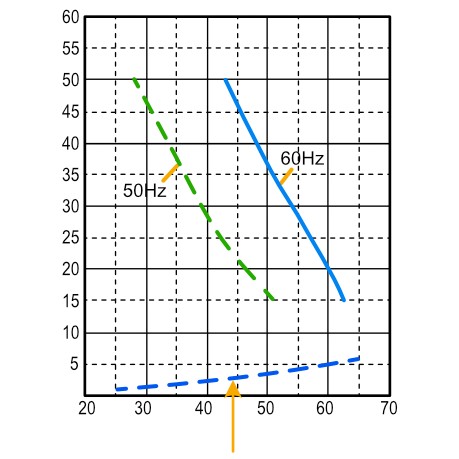

External type

Coolant pipe diagram

RKE2200B1-V

Available cooling power (kW)

Liquid temperature (℃)

Condition

Room temperature: 32℃

Cooling water: Water pipe

Water volume that the pump can supply: 39 liters per 54 minutes

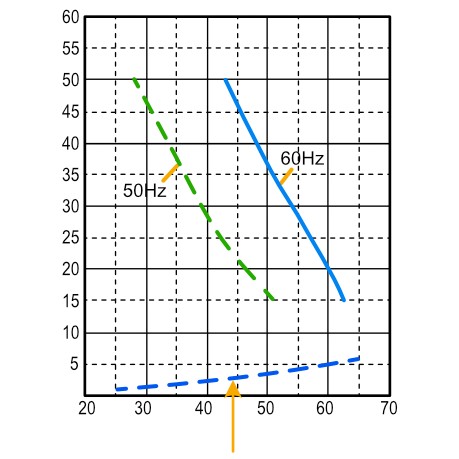

Water pump inlet pipe diagram

RKE2200B1-V

Water volume (liters/minute)

Condition

Room temperature: 32℃

Cooling water: Water pipe

Water volume that the pump can supply: 39 liters per 54 minutes

Download documents